| User name | A bobbin paper factory |

Machine No. / type of (board) paper | Ring pressure requirement ≥ 18, interlayer requirement ≥ 350 |

Type / speed / width of paper machine | Seven garden net paper machines, 360 ~ 420g / m2, about 120m / min, with a daily output of 230 tons. |

| Slurry ratio | 100% national waste |

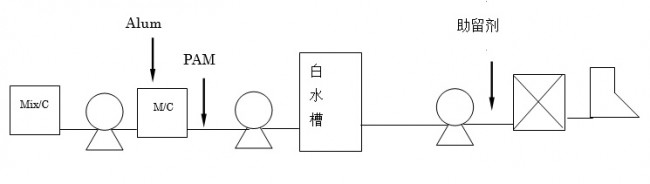

Addition process of various chemicals in pulp (addition position of chemicals and addition amount per ton of paper or pulp)

Dry strength agent (PAM): 15 ~ 20kg / t paper (different according to quantitative or size change)

Aluminum sulfate in pulp (alum): 5 ~ 8kg / t paper

Application effect of dry strength agent PAM:

① By adding PAM of our company into the slurry, the annular pressure and interlayer amplitude are increased by about 20%;

② Improve the retention of fine fibers, reduce the white water load and reduce the pressure of sewage treatment;

③ By adding PAM, customers further optimize the papermaking process (reduce the amount of inter layer spray starch);

④ Improve the operation of the paper machine, reduce paper breakage and improve the speed of the paper machine, and increase the production efficiency.

Headbox system analysis

| project | PH value | Conductivity US / cm | PCD ueq/1 | Copying temperature ℃ | |

| Net cage | 6.45 | 5000 | -350 | 50 | |

| plain water | 6.48 | 5200 | -390 | 50 |