| User name | A large box board paper factory |

| Machine No. / type of (board) paper | Burst index shall be ≥ 3.8kpa · M ²/ g |

Type / speed / width of paper machine | The triple screen paper machine is 150g / m2, the paper type is about 800m / min, and the daily output is 1000 tons. |

Slurry ratio | A small amount of wood pulp vermicelli on the surface Core bottom layer American waste, Canadian waste, etc |

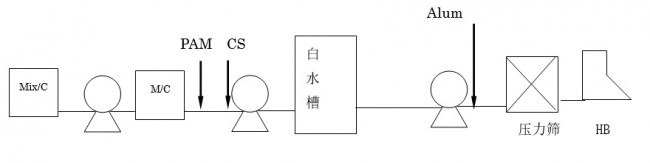

Addition process of various chemicals in pulp (addition position of chemicals and addition amount per ton of paper or pulp)

Dry strength agent (PAM): 20 ~ 30kg / t paper (different according to quantitative or size change)

Starch in pulp (CS): 5 ~ 10kg / t paper

Aluminum sulfate in pulp (alum): 10kg / t paper

Application effect of dry strength agent PAM:

① By adding PAM of our company into the pulp, the paper strength is greatly increased (the bursting strength is increased by about 20%);

② The amount of CS in the slurry is reduced, the COD value of white water is greatly reduced, and the pressure of sewage treatment is reduced;

③ Improve the retention of fine fibers, reduce the white water load and reduce the pressure of sewage treatment.

④ The customer further optimized the sizing process by adding PAM (reducing the proportion of waste wood pulp agent)

⑤ The operation of the paper machine is improved, the paper breaking of the paper machine is reduced, the speed of the paper machine is increased, and the generation efficiency is increased.

| Headbox system analysis | ||||

|---|---|---|---|---|

| project | PH value | Conductivity US / cm | PCD ueq/l | Fabrication temperature ℃ |

| noodles | 7.18 | 1248 | -200 | 50 |

| core | 7.17 | 1501 | -246 | 55 |

| bottom | 7.13 | 1391 | -208 | 46 |

Sizing process | Sizing method | Press sizing | ||

| Sizing agent / alum / starch | Surface sizing agent 2kg / t paper | |||

| PH / conductivity / T | Reverse ph2.6 conductivity / 2840us / cm, coating temperature about 80 ℃ | |||

| Drying pressure after paper machine | About 80 ~ 150kPa | |||

| Sizing degree control standard | 1min COBB≤40g/m2 | |||